1. Introduction to CNC milling machines

The ability of CNC milling machine to bring precision, automation and versatility to the machining processes has greatly advanced the manufacturing sector. The CNC, which is the contrived abbreviation for computer numerical control, defines the mechanism employed in imbuing the machines to carry out intricate tasks, including cutting, drilling, and shaping of different materials ranging from metals and plastics to wood. Today, this technology is considered essential in many economic sectors demanding precision, including those of aerospace, automobiles, electronics, and medical instruments.

2. Types of CNC milling machines

Types of CNC milling machines vary, each dedicated to specific production areas. For example, vertical CNC milling machines have vertically oriented spindles. Commonly used for tasks that demand high precision in shape, these machines include those that are used to shape flat surfaces or process highly complex designs. With their versatility and ease of use, they are perfect for small to mid sized projects.

But horizontal CNC milling machines have horizontally oriented spindles to cater for heavy duty cutting tasks. These machines are stronger and sturdier and are perfect for working with heavier materials. For projects involving complex, three-dimensional shapes, multi-axis CNC milling machines are designed. These machines can use more than three axes to rotate and position the workpiece in multiple directions, enabling intricate work that would be difficult or impossible with simpler machines. CNC milling machine manufacturers keep on developing new variations of these types so that they will meet the diverse demands across the world.

3. Key components of CNC milling machines

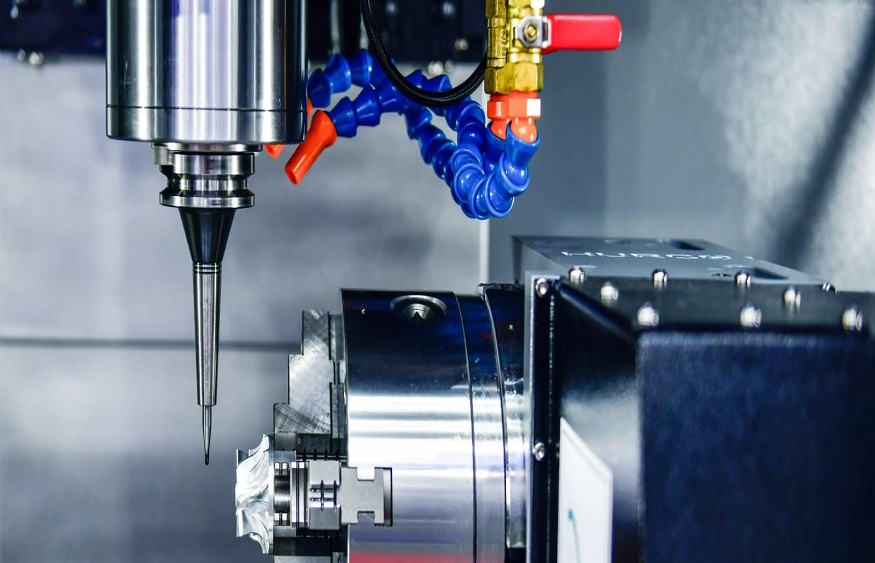

A CNC milling machine is made up of various parts working together to perform high precision machining tasks. The machine’s brain is the CNC controller, which processes instruction inputs and directs movements on the axes. It is responsible for the synchronised movement of the motors and the drives to brace during the process of machining.

The cutting tool, or end mill for short, which removes material from the workpiece, is another vital component. The cutting tool is attached to the spindle and rotated at high speeds to enable effective cutting. By arranging the workpiece and worktable according to the given programmed instructions, the worktable is provided with a position and moves only concerning the workpiece. However, like most CNC milling machines, many of these also come equipped with a coolant system to cool the tool during cutting to prevent overheating and thus achieve quality. These components are constantly improving to enhance performance, precision and efficiency.

4. Applications of CNC milling machines

CNC milling machines are very versatile and are used in numerous industries. In aerospace, they are essential for manufacturing critical components such as engine parts or airframe items, which must adhere to strict safety standards. Because of the precision and complexity needed in this field, CNC milling technology is necessary to produce quality and reliability.

In the automotive sector, these machines make it possible for mass production of such components as engine blocks or transmission housings, enabling manufacturers to meet fast production requirements. CNC milling is also used in the medical field since it is utilised to manufacture special equipment like prosthetics and surgical instruments, where precision is crucial. In electronics, CNC milling also creates intricate components such as circuit boards and device housings. Manufacturers continue to innovate, designing improved machines tailored to the special needs of specific industries, improving performance and reliability.

5. Advantages of CNC milling machines

In aerospace and medical device manufacturing industries, where even a slight error can have grave consequences, CNC milling machines are widely respected for their extraordinary precision. The tolerances that these machines can produce are superior to what’s possible with manual machining techniques, delivering quality part after part. The requirement for this high level of accuracy is essential to maintain standards in critical applications.

CNC milling machines further add to productivity by running in continuous operation. Once programmed, they can run on their own with little human intervention to decrease downtime and increase output. As such, the efficiency of this process results in decreasing labour costs and decreasing errors, ultimately reducing production costs over time. Additionally, their flexibility lends itself to performing a multitude of tasks ranging from cutting to engraving, which makes them a worthwhile option for both custom and large scale production. However, manufacturers are always developing newer, quicker machines, more durable machines and user-friendly machines, making them more appealing. With these advancements, CNC milling machines become not only more efficient operationally but also even more user-friendly, all to draw businesses that want to leverage the most out of their manufacturing processes. The CNC milling will only become more and more beneficial as the technology continues to advance, making it an invaluable tool for any production environment.

6. CNC milling machine manufacturers and future trends

CNC milling machine manufacturers are ahead of the curve regarding technological advancements, especially when it comes to integrating artificial intelligence (AI) and machine learning into the systems. CNC machines can learn from their operations, increasing their efficiency and reducing material waste through real-time optimisation of processing. Predictive maintenance also relies heavily on AI to foresee maintenance needs, minimise downtime and extend the life of the machine. Meeting the increasing demands of modern manufacturing requires this adaptability.

In addition to AI, hybrid manufacturing techniques combine CNC milling with 3D printing. This approach combines the advantages of both additive and subtractive manufacturing, whereby complex shapes are printed in 3D and then thoroughly finished with CNC milling. The trend also includes a greater focus on achieving sustainability as the industries intend to reduce the impact of their production processes after the implementation of energy-efficient machines, recyclable materials, and eco-friendly coolants. These trends will establish a more responsible and efficient future of manufacturing.

To conclude, CNC milling machines have turned out to be an inevitable part of today’s manufacturing process due to their accuracy, flexibility and invasive efficacy. The CNC milling machine manufacturers are improving the technology of the machines so that there will be increased demands and the machines will fulfil them uniquely. CNC milling machines have seen their evolution and will continue to be an important tool for manufacturers to facilitate high quality results in a very competitive market.